Nagoya City Science Museum

TOP > Exhibition Guide > Keyword Search > Starting with "A" > airplane > Airplane

Airplane

Purpose of Exhibition

The airplane is "the king" of all machines. It is not a machine that any country can make. It is said that only "developed" countries with high level manufacturing industry can make it. Making an airplane is a barometer that shows one country's national power.

Here, we will explain about the Chubu region and the aircraft manufacturing industry as a theme.

Additional Knowledge

[The Chubu Region and Aircraft Manufacturing]

The Chubu area is a center of automotive manufacturing, but at the same time, it is also a base for manufacturing aircrafts*.The main factories of the three major domestic aircraft makers are located in this region. Furthermore, in the three prefectures of Tokai region, many aircraft-related small businesses have their headquarters. As a result, 50 % of parts production for aircrafts in our country takes place in this region.(*aircrafts include helicopters, airships, balloons)

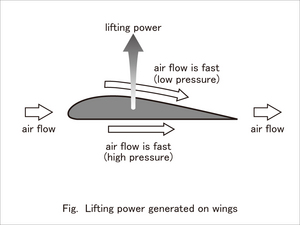

[Flying Principle]

The shape of the wing is important. Long at the cross section, there is an inflated curve at the top, and the shape at the bottom is close to a straight line. According to experimental results, the air-flow directed over the wing is fast, and the air-flow at the bottom is gentle.There is a principle** that the portion where the air flow is gentle gets high pressure, while the portion where the air flow is fast receives low pressure. As a result, there is enough power generated to lift up the wings from bottom to top.This is called the lifting power. The aircraft can fly according to a balance of weight and power. (**Bernoulli's principle)

[Materials to make a Plane]

To float a giant aircraft, a light and unbreakable material is used.

It's not the steel that is used widely in various industries, but aluminum alloy (duralumin) is a typical material used.

Recently, CFRP (Carbon Fiber Reinforced Plastics) has become common. The manufacturing process must be implemented with a theory, method and technique that are different from the steel used in automobile manufacturing.

[Safety]

Aircrafts are manufactured with the principle "Safety first". A train and car can be stopped in case of emergency but an airplane's engine will not be turned off during the flight in any case. Rather than a new approach, reliable technology is preferred.

For example, when bonding metal to metal, instead of welding as a car and train are done so, rivet joints are used. Rivets were a previously used older form of technology in construction and shipbuilding. In order to pursue safety, an old but particular technology is paramount.

Most importantly, reliability cannot be excluded from aircraft manufacturing. To keep flying several thousand meters high with a speed of 1000 kilometers per hour for decades, rigorous certification tests are required. Experimental measurements are repeated countless times to confirm safety. Thus, it is an industry that is specific and hard to compete in, in which a long-term inspection is required to obtain reliability.

[Limited production]

Aircrafts are not manufactured in large numbers as cars are. When the main wings of the U.S. Company Boeing B787 were produced, the production facilities were expanded. It was reported that the structure of production could only produce 10 airplanes per month.

Whereas tens of thousands of cars can be produced, only some tens to hundreds of airplanes are manufactured. In such a small rate of production, it is important to rely on manual work. An accurate technological skill and ability are required.

CooperationMitsubishi Aircraft Corporation College of Nakanippon AviationArticle by Koichi Mabuchi, curator