Nagoya City Science Museum

TOP > Exhibition Guide > Keyword Search > Starting with "P" > plasticity > Pressing

Pressing

Purpose of Exhibition

Pressing is the technology, in which a work piece is placed between a pair of metal molds and applied strong pressure to, which changes the sheet into the same form as the metal mold. It also pulls out as a circle and a rectangle and makes holes. In this exhibit, it is possible to understand more deeply about pressing which is a most important technology for mass production.

Additional Knowledge

Before the explanation of the pressing, let's see the two properties of metal: plasticity and ductility. Plasticity describes the deformation of a material undergoing non-reversible changes of shape in response to applied force. Ductility is one of the properties of plasticity. That describes the extent in which solid materials can be plastically deformed without fracture.

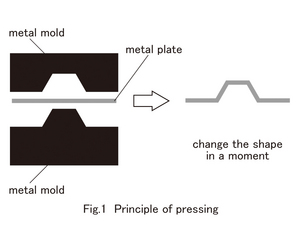

When putting a metallic material between a pair of metals and applying a large compressive stress, the metallic material is deformed into the same form as the metal molds (Figure 1). After the deformation, the metallic material never returns to its original shape. It is understood that pressing is based on the characteristics of plasticity and ductility.

The smooth curved surface of a car body is produced by pressing. In order to suppress fuel consumption, it is necessary to slim down the car body weight. Therefore, an extremely thin steel sheet is used for it. The pressure to the steel sheet is required to be as uniform as possible when this sheet is pressed. If there is a tiny projection or dent in the metal mold, an intensive pressure is applied to where these projections and dents are when pressing. Consequently, the steel sheet cracks. First, metal molds are made by a craft machine tools. Afterwards, they are polished up elaborately by manual work.

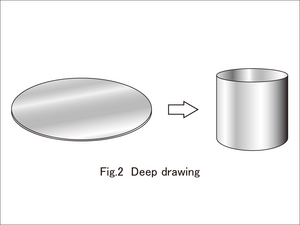

In case of pressing three-dimensionally, it could be pressed little by little several times. For example, when making a metal cup, it is pressed little by little with disc-shaped metal and is formed into the final shape. This is called deep drawing (Figure 2).

It is not that a metal cup cannot be made by the method of making a cylinder by bending a rectangular metal and welding each edge, and then welding with a round metal.

In addition, by this method, it cannot be produced in a large amount in a short time, and costs more. Therefore, pressing technology -Deep Drawing- is chosen in order to produce large amounts of cups industrially.

Mr. Masayuki Okano, president of Okano Kogyo in Sumida ward, Tokyo (He refers to himself as a representative of his employees), became famous for this pressing technology and often appears on TV.

Mr. Okano first became known for manufacturing a case for lithium-ion batteries in a cell phone with pressing technology.

The cell phone battery case has a very thin matchbox-like shape. The lithium-ion battery case production cannot adopt the method in which metal is cut out of interior elevation and stuck together. Leaking from the connected part, it becomes a serious problem because it has strong corrosiveness. Not only that, because a thin stainless steel is used, which is easy to crack, a high level of skill is required for the pressing.

Deforming a sheet of stainless steel gradually, seeing how many times and how much the sheet needs to be bent and processed to make it into a thin matchbox at the end, and applying force - not like compressing, but rubbing at times _ is a difficult process. Most rational procedures have been laid out based on past experiences as to how much pressure fractures metal. Of course, the processing does not always succeed as expected. New technology and skill will be developed by struggling through numerous successes and failures.

Finally, a brief explanation about hole-punching, which is another part of pressing, will be given. With circular or square industrial tools (with a blade) applied to metallic materials and applying pressure, hole-punching can be carried out. This is referred to as "Nukiuchi".

Cooperation:JAPAN ALUMINIUM ASSOCIATIONArticle by Koichi Mabuchi, curator