Nagoya City Science Museum

TOP > Exhibition Guide > Keyword Search > Starting with "M" > melt > Welding

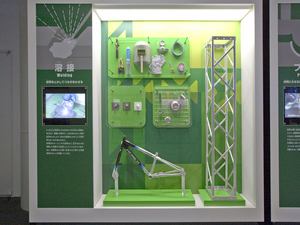

Welding

Purpose of Exhibition

Welding is an important technique used to join metals together. It plays an important role in the field of manufacturing power plants, automobiles, Shinkansen (bullet train) and so on. It is said that welding was used for bronze bells in the Yayoi Era. In this exhibition, we would like you to learn and understand about welding techniques that have been used from ancient times to today.

Additional Knowledge

[What is welding?]

When you join two metals together, you may think about using an adhesive. However, when it comes to welding, the base materials (the materials you would like to join together) should be melted physically. The characteristic of welding is that the welding point has continuity on the molecular level. In that regard, the joint method is different between the welding and the use of adhesive.

[Arc Welding]

There are a variety of welding styles. The most important is arc welding. What we just refer to as "welding", actually means arc welding.

The base material and the weld rod are melded and joined by generating an arc (electric spark) between them. We often use this method for welding iron material. If the welding goes smoothly, the strength of the welded part becomes stronger.

As you can see in "Figure 1", two cords come from the arc welding machine. One is connected to the weld rod through the retainer, which is called a "welding torch". The other is connected to the metallic plate, which holds the base material as a grounding wire. The welding is processed by touching the edge of the weld rod attached to the welding torch lightly to the base material and generating the arc.

A person who does welding is required to be highly skilled.

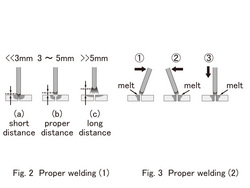

First of all, the distance from the base material and the weld rod should remain between 3 to 5 millimeter. The arc is not generated when the base material and the weld rod are joined together. Also, arc welding is not possible if they are too far apart (Figure 2).

Secondly, the direction of the weld rod should be changing rhythmically. If you set the weld rod at a right angle to the welded part and bring it straight in, the welding does not goes smoothly. You have to change the direction of the weld rod like shaking the head left and right and putting the weld rod at a right angle to the welded part (Figure 3). The repetition of this work is the welding.

When welding, the light produced is very strong. It is required to use black glasses to protect the eyes. The welding point must be probed before beginning work.

[Welding for Shinkansen (Bullet Train)]

Recently, the friction stir welding technique has come under the spotlight. This method was used for the N 700 series trains.

Friction stir welding is a joining process in which two base materials are matched up and the pin is pushed into the boundaries and then by pushing and rotating with a strong force, the friction to the base material is created.

For making the Shinkansen (bullet train) N 700 series, aluminum was used for more efficient weight. Aluminum has some disadvantages, though. The melting point of aluminum is low and difficult to do arc welding. When it comes to friction stir welding, even if frictional heat is applied, it does not reach the melting point. Friction stir welding plays a vital role providing lighter materials for the Shinkansen and improving the environmental design.

Cooperation: Nagoya City Technical High SchoolArticle by Koichi Mabuchi, curator